-

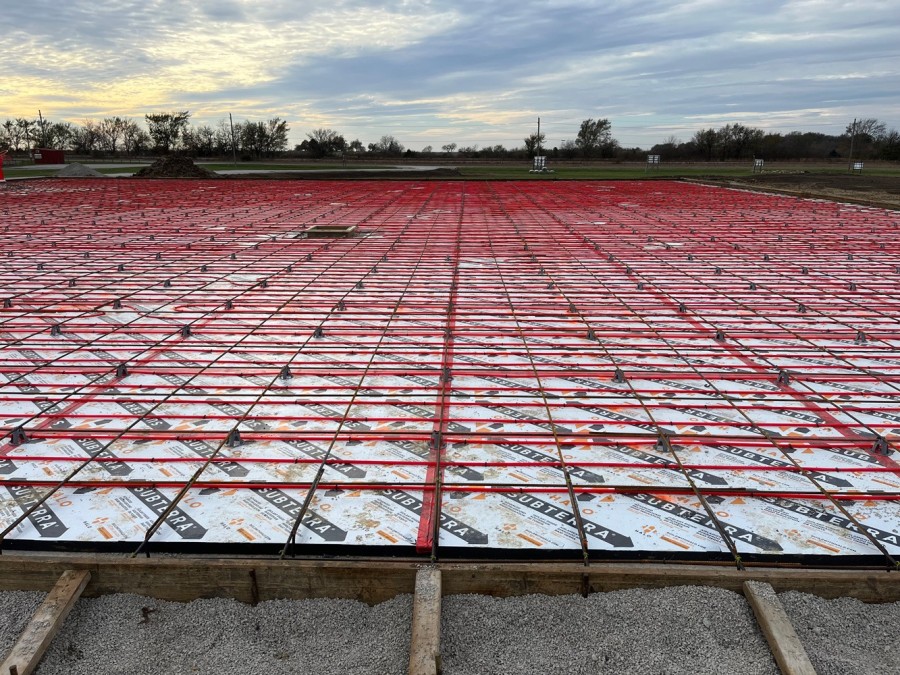

propane fed floor heat in footing and under slab

-

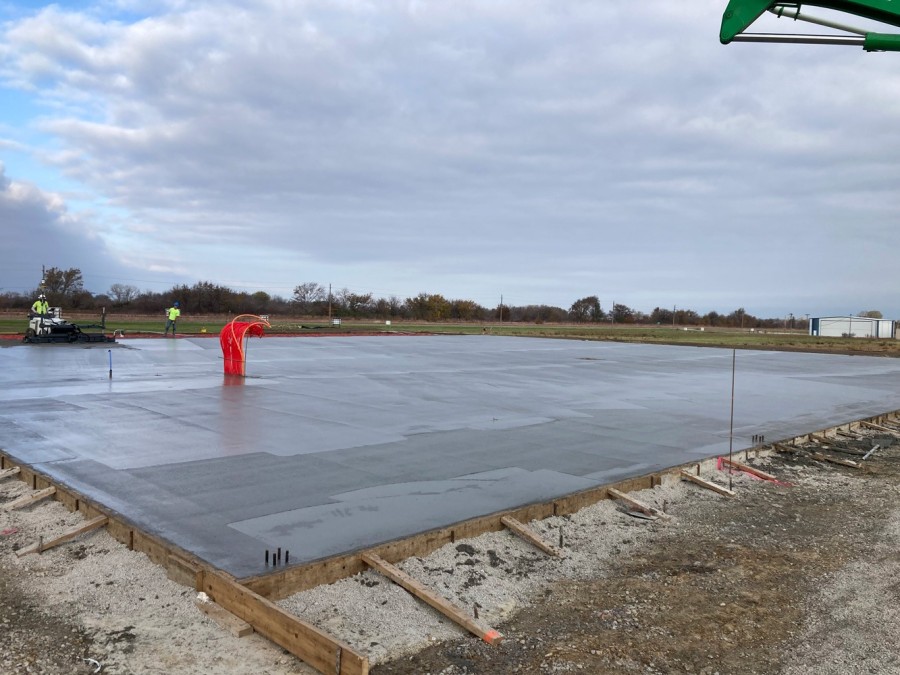

pouring concrete over propane fed floor heat

-

heated concrete slab

-

concrete foundation for pre-engineered metal building

-

erecting pre-engineered metal building

-

plumbing for airplane hangar

-

pouring concrete runway access

-

concrete flatwork being completed by our concrete contractors

-

pre-engineered metal building contractors installing building

-

airplane hangar pre-engineered metal building

-

70' x 16' higher power hydraulic door

-

offices within airplane hangar

-

interior of hangar prefab steel building

-

airplane hangar with big ass fans

-

new airplane hangar for small planes

-

prop plane exiting hangar's large hydraulic door

-

pre-engineered metal hangar

-

aerial view of air plane hangar steel building

-

airplane taking off at air port

-

aerial view of airplane hangar installed at Bulter, MO Airport

BCS Aerial

Project Summary

BCS, located in the Butler, MO area, is a valued customer of Koehn’s, marking our fifth collaborative project. With BCS’s continued growth, they approached us to construct a hangar building at the Butler Memorial Airport to enhance the aerial operations of their business. Koehn’s served as the general contractor for this project, helping BCS with the civil engineering process and working together on the FAA requirements in regards to the building and interior design for the finished space.

The building is strategically placed for easy access onto the Butler Airport runway. A standout feature on this building is the massive hydraulic door, designed for easy entry and exit of the aircraft. The building serves as protection for the plane and dedicated space for scheduled maintenance on aircraft.

The finished space has two levels and numerous windows to the outside and a couple windows inside to overlook the hangar space. The full height wall liner protects the insulation and provides a bright, durable interior. The ceiling is also fully lined with a perforated panel to help with reducing sound in the large space. The entire building has a radiant floor heat system with 3 – 200,000 BTU boilers. All the interior finished spaced is cooled with its own HVAC system. In the Spring and Fall months when temperatures are at their best, you can open up the massive hydraulic door and overhead door and turn on the large ceiling fan for good airflow throughout the large space.

Project Specifications and Products Used

Pre-engineered Metal Building

- 120’ x 125’ x 19’

- 1:12 Roof slope, Gable

- Clear height of 20’ 10” at peak

- 1 - 70’ x 16’ Higher power Hydraulic Door, Truss Painted to match door panel color

- 4’’ blanket insulation in roof and walls (R-13)

- 2 - pre-assembled 30/70 entry doors with half glass and dead bolt, with auto closures

- 1 - 20’ x 16’ double sided steel overhead door

- 11 - 40/30 Andersen 100 series windows

- Full height wall liner and ceiling liner

Concrete

- Foundation, piers, slab, and exterior concrete

Mechanical

- Propane fed floor heat with 3 – 200,000 BTU boilers and 2” foam in footing and under slab

- HVAC in finished area

- 16’ Big Ass Fans

Electrical

- Full electrical package

Plumbing

- Rough in plumbing for below slab 1 toilet and 3 sinks

- Septic System

Interior Framing and Finish

- First floor consists of 1 bathroom, 1 kitchen, and 2 offices

- Second Floor consist of 3 – rooms that can be use as storage, living quarters, or office space

Project Location

Start Your Next Construction Project with Koehn Building Systems

If you want to learn more about working with our construction company or are ready to get a quote, we encourage you to reach out to us by calling us at 417-395-4305 or by filling out our contact form online. We promise to reach back out as soon as possible, and the majority of quotes are delivered within 1-2 weeks of our initial project scope conversation. We appreciate the opportunity of working with you and look forward to hearing from you soon.

Content Reviewed by Steve Koehn